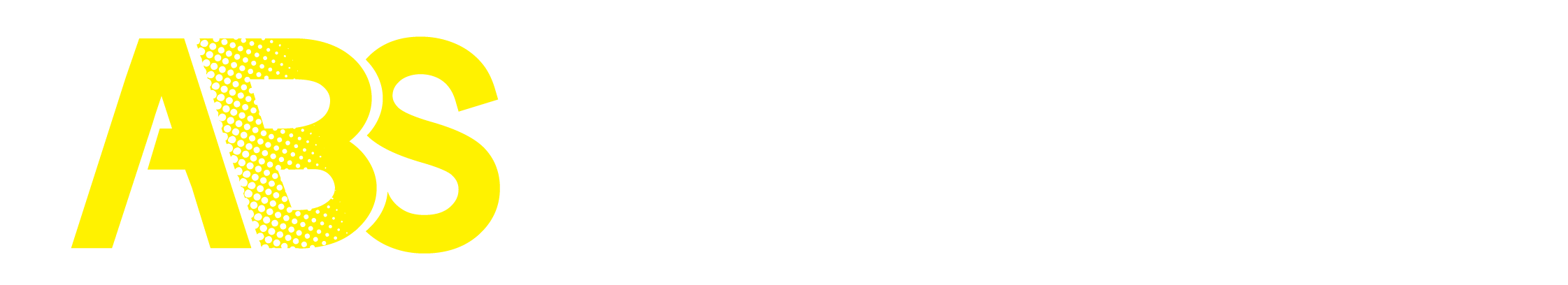

ABS Blast Rooms

Abrasive Blast Systems has four decades of experience designing, engineering, and installing blast rooms with varying requirements for size, complexity, and schedule. Whether you’re looking for a small, pre-fabricated blast room, or a large, custom room with robotic blast functionality, ABS has your solution.

- Custom ‘On-Site Installation’ Blast Rooms

- Pre-Fabricated, Turnkey Blast Rooms

- Designed for light work pieces or heavy equipment

- Monorail Systems

- Automated/Robotic Blasting Systems

- Multiple Reclaim Flooring System Options

- Abrasive Blast System’s proprietary blasting system design

- Abrasive Blast System’s proprietary dust collection & air filtration systems

Scroll down to learn more about our blast room options, or contact us to discuss your upcoming project!

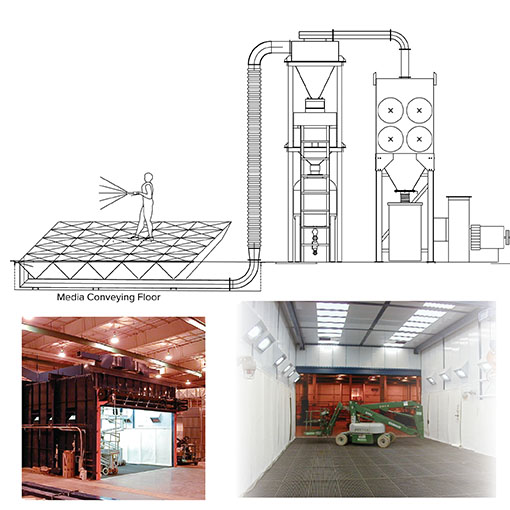

Full Floor Recovery Systems

Combined with ABS’ High-Static Cyclone/Reclaimer and our 99.99% efficient Dust Collection Systems, the ABS Full Floor Blast Recovery System is the premium choice for the customer who needs a low maintenance, highly efficient system designed to unique specifications.

- Continuously recycling floor, no sweeping

- Low Maintenance compared to mechanical systems

- Various Layout Configurations

- High-Static Cyclone with Adjustable Air-Wash

- Automatic Reverse-Pulse Dust Collection System (cartridges rated 99.9% efficient @ 0.5 microns)

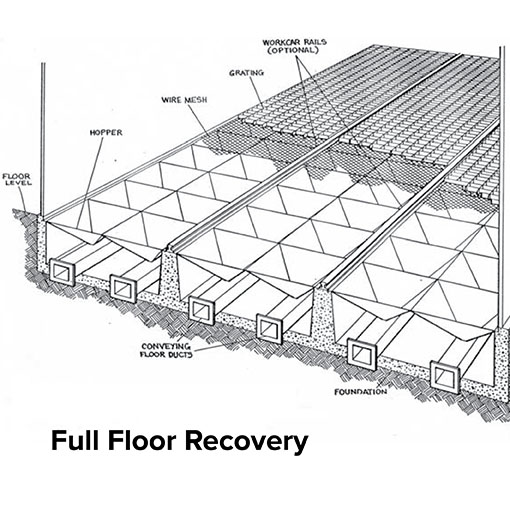

Sweep-In Recovery Systems (Below Floor)

This system is ideal for situations where the blast room is being used for heavy equipment that requires a more robust flooring, or when the blast room is large enough to make the Full Floor Recovery System uneconomical.

While the Sweep-In System is more manually intensive, it still comes with the standard features and advantages of an ABS Blast Room:

- Affordable

- Low Maintenance

- Various Layout Configurations

- 1600 CFM Reclaimer (AW)

- High Efficiency Cyclone with Adjustable Air-Wash for fine-tuned cleaning

- 1600 CFM Dust Collector

- Automatic Reverse-Pulse Dust Collection System (cartridges rated 99.9% efficient @ 0.5 microns)

Sweep-In Recovery Systems (Above Floor)

This recovery system allows for increased flexibility and affordability in the blast room design and is a dependable solution for many applications.

- Our most economical solution

- A Flexible Solution for Unique Scenarios/Environments

- Low Maintenance

- 1200 CFM Reclaimer (AW)

- High Efficiency Cyclone with Adjustable Air-Wash for fine-tuned cleaning

- Automatic Reverse-Pulse Dust Collection System (cartridges rated 99.9% efficient @ 0.5 microns)

- 1200 CFM Dust Collector

*Shown with a 10 cubic foot blast & storage system